- Home

- Products

- Centrifuge technology

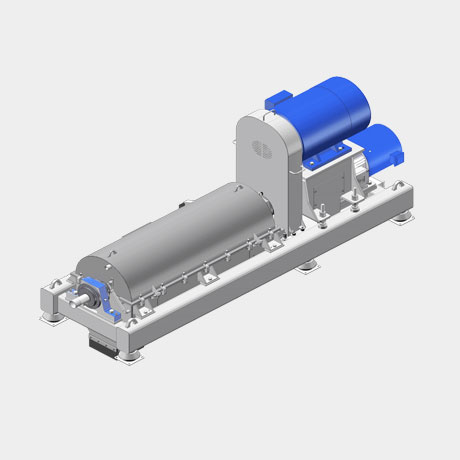

- DSE ZR15046

DSE mobile decanter ZR15046

centrifuge

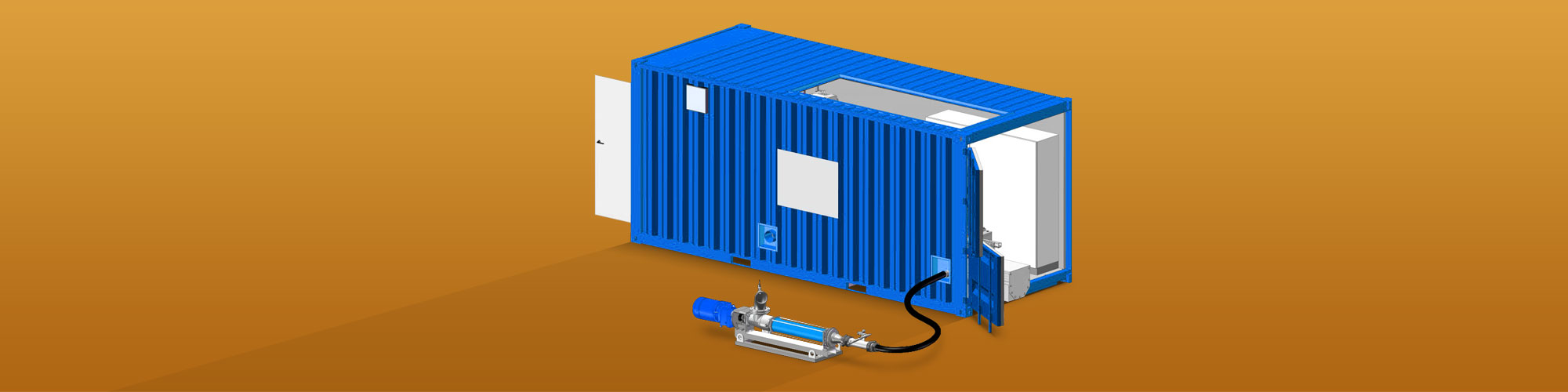

The compact DSE mobile centrifuge decanter ZR15046 is a self-contained, high-dewatering separation unit and comprises a 20 ft. heat-insulated container, a high-performance solid bowl centrifuge, an integrated powder polymer mixing and dosing unit, an eccentric screw feed pump, a spiral conveyor system, a central control cabinet, heating system, and further accessories.

Details

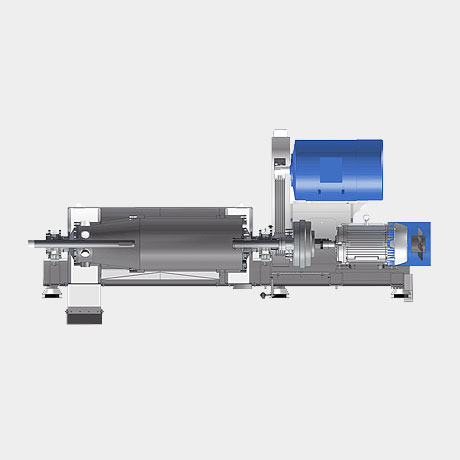

The ZR15046 Decanter with variable speed drive (VSD) is a solid bowl decanting centrifuge and specially designed for high dewatering performance, high material throughput and high clarification performance at the same time in municipal and industrial applications.

High torques and high solid loadings are easily to handle due to its hd industrial model design. New drive technology has been combined with durability and reliability in a product that is easy to operate and fully adjustable. The DSE ZR15046 is directly fed by a variable eccentric screw pump..

The DSE mobile centrifuge decanter ZR15046 including mixing and dosing unit, control panel, spiral conveyor, piping and wiring is built into a 20 ft. container (dimensions as per ISO 668; 6 058 x 2 438 x 2 280 mm) and allows therefore reduction of assembly time to a minimum.

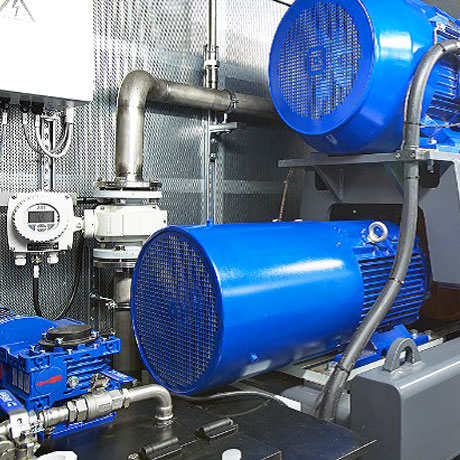

The VSD packages allow controlled impact of motor drive power to the centrifuge bowl, to the screw and to the feed pump. The ability to vary the speed of the bowl, the Screw and the feed pump power unit independently allows the centrifuge to be operated in the most efficient and productive manner for the intended application and wastewater condition.

The centrifuge rotating assembly is made from advanced centrifugally cast duplex stainless steel. Non-rotating components which come in contact with the process material are manufactured of corrosion resistant stainless steel. The modular centrifuge base is manufactured from carbon steel with industrial epoxy coatings. The centrifuge rotating assembly is housed in a stainless steel enclosure with fully wear protected components where the solids and liquids are discharged. All parameters are fully controlled by plc and can be applied by the operator, such as torque control and unbalance control. These parameters are self-controlled and regulated for safety reasons.

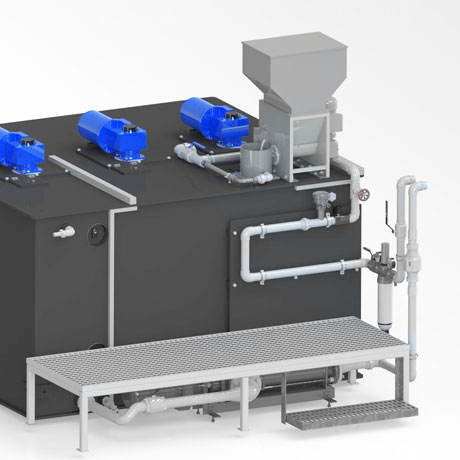

The integrated automatic powder polymer mixing and dosing unit is selected for preparation and dosing of polymer solutions for feeding of the DSE centrifuge decanter ZR15046. The unit control is user-friendly integrated in the touch screen display and a programmable logic controller (PLC) of the whole machine. This integrated control system allows an automatic preparation and dosing process. The dosing of the polymer solution into the slurry circuit is controlled by measuring of flow rate.

| Length | 6.058 mm | |

|---|---|---|

| Width | 2.438 mm | |

| Height | 2.891 mm | |

| Total weight (approx.) | 8 800 kg |

| Capacity (max.)* | 10 – 36 m³/h (at 1.25 kg/l) | |

|---|---|---|

| Solid output (max.)** | 7 t/h | |

| Inside bowl diameter | 460 mm (18“) | |

| Bowl length | 1.500 mm | |

| Bowl speed (max.) | 2.960 1/min (bei 50Hz) | |

| Differential speed | 0.5 – 50 1/min | |

| Torque (max.) | 9.600 Nm |

* Subject to solids loading, slurry properties, soil type properties and properties along with operating conditions!

** with a moisture content ranging between 25 to 40%

| Flow rate (at 60 min maturing time) | 4.000 l/h | |

|---|---|---|

| Flow rate (at 30 min maturing time) | 8.000 l/h | |

| Dosing pump (against max. 3 bar) | 700 – 6.000 l/h |

| Bowl drive | 75 kW | |

|---|---|---|

| Conveyor drive | 37 kW | |

| Feed pump | 11 kW | |

| Polymer dosing unit | 2.2 kW | |

| Others | 10 kW | |

| Voltage | 400 V / 50 Hz |

Contact

Gewerbestraße 11a

26553 Dornum

Germany

Tel: +49-4933-4269975

E-Mail: info@diff-speed.de