DETAILS

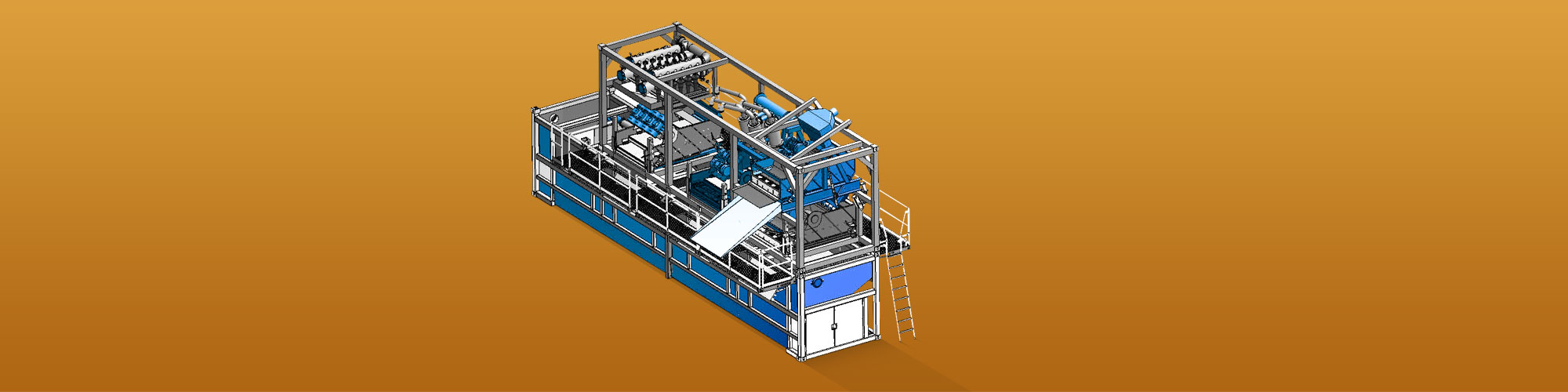

The DSE 400 is a compact separation plant and specially designed for processing of slurries and removal of mineral solids from the slurry circuit in drilling or other associated applications with a high content of silt.

Instead of a collection of equipment from various sources, the DSE 400 is a field-proven network of separation components specifically designed to function as a single unit. During each separation stage, a maximum of solid particles is removed from the slurry. The modular system guarantees continuous and fast advance rates, reducing downtimes to a minimum. The innovative screening technology combined with hydrocyclones constitutes a complete recycling concept, providing optimal removal of critical fine particles down to 20 microns and guaranteeing constant slurry properties.

.

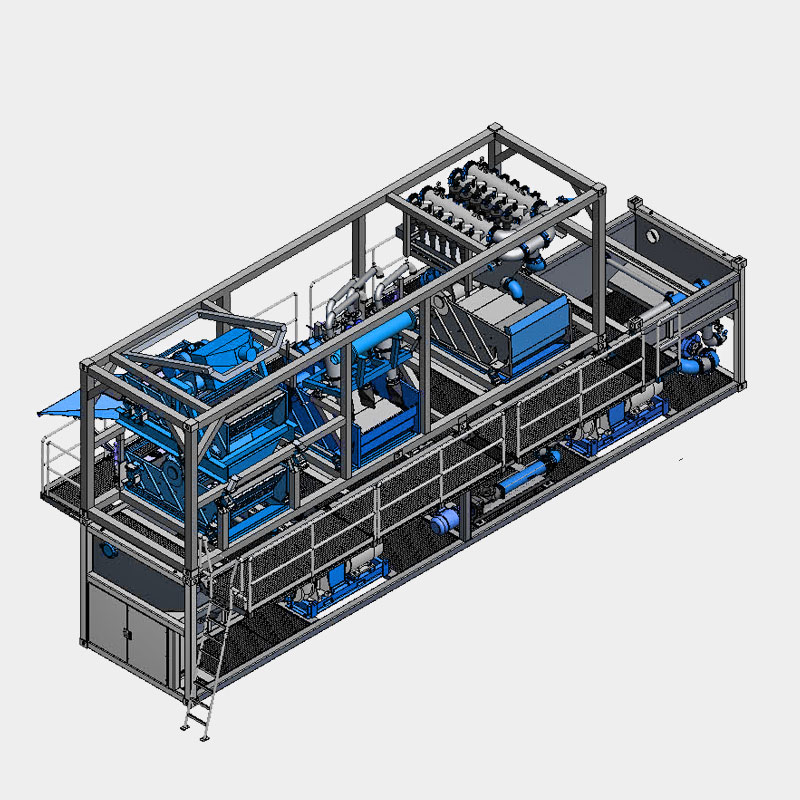

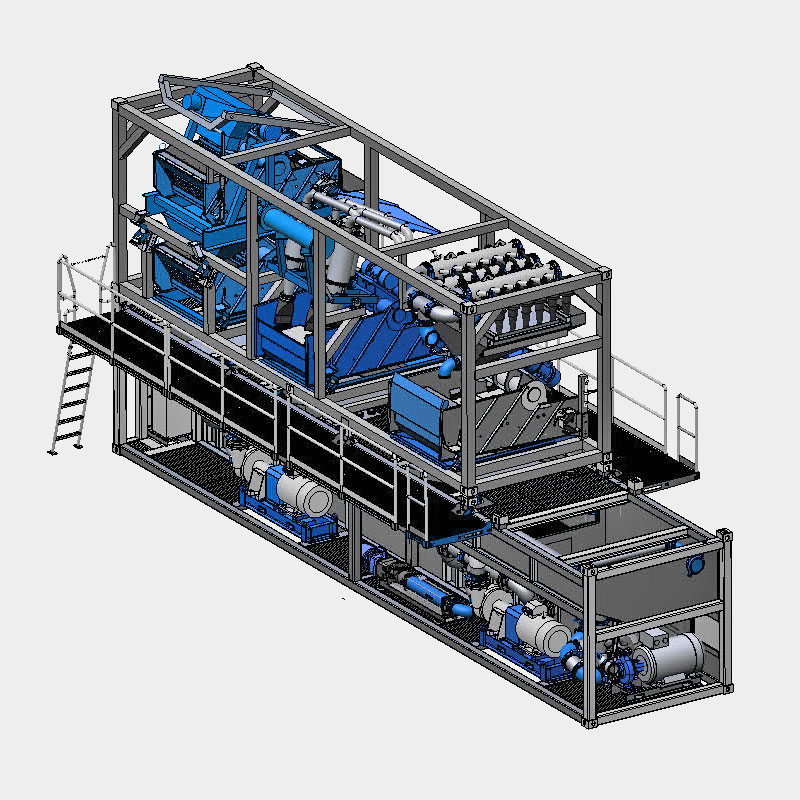

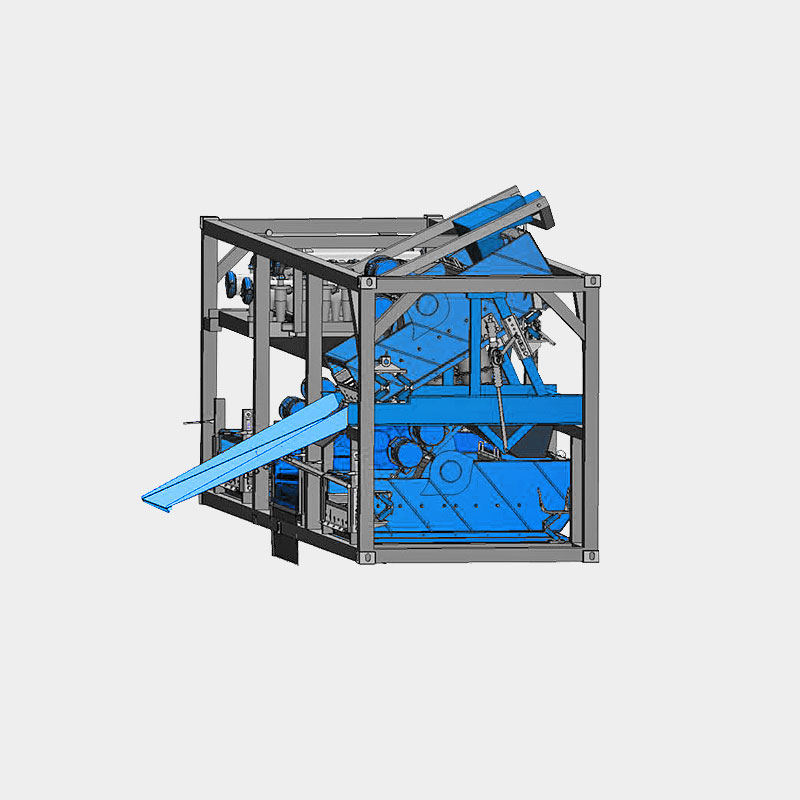

The DSE 400 is composed of one (1) linear motion vibration prescreening machine for separation of coarse solids such as gravel and clayballs, one (1) linear motion vibration screening machine for separation of coarse solids such as gravel, pebble and coarse to medium sand, four (4) hydro-vacuum-cyclones with a cone size of 12”, one (1) linear motion vibration screening machine for removal and dewatering of the hydrocyclone’s underflow containing solids such as fine sand and silt, twenty-four (24) multicyclones with a cone size of 4”, one (1) linear motion vibration screening machine for removal and dewatering of the 4” hydrocyclone’s underflow containing solids such as fine sand and silt, one (1) 40 ft. process tank with integrated agitation and two (2) integrated WARMAN HD-centrifugal feed pumps, one (1) central control cabinet and accessories, one (1) KSB Etanorm feedpump TBM.

Adjustable discharge chutes, fold-away platform and pluggable railing for safe working and good access provide a plug-and-play solution. Assembly time is therefore reduced to a minimum. Feeding of shakers and cyclones is accomplished by an integrated fixed piping and wiring system in a minimal footprint. All components, such as shakers, cyclones and funnels, are mounted in a 30’ container frame, all electrical wiring is pluggable into each machine compartment.

All cables are fixed at the tank section, no machines with hanging cables, when the 30’ frame is lifted.

The whole machinery is divided in two compartments, when transported, one 40’ tank and one 30’ frame with all equipment fixed into it.

The left space of 10’ at the top of the tank is recommended for using the DSE ZR17254 decanter unit or the DSE ZR15046 decanter unit, each installed in a 20’ insulated container, with included polymer device.

The single-deck vibration screening machines can easily and flexibly be equipped with a wide range of different DSE panel screens made of steel or polyurethane which are available from 10 mm mesh width down to 45 μm.

Tank (incl. pumps and folded working platform)

| Length | 12 160 mm |

| Width | 2 439 mm |

| Height (with unfolded working platform) | 4 542 mm |

| Height | 2 438 mm |

| Length | 9 120 mm |

| Width | 2 439 mm |

| Height | 2 895 mm |

| Height (installed) | 6 200 mm |

| Total weight (approx.) | 25 000 kg |

| Nominal fluid capacity (max.)[3] | 400 m³/h |

| Total power supply | 190 kW |

(without winter package)

[1] approximately; assembled on site

[2] subject to change

[3] The capacity of the DSE400 is subject to the slurry properties, solids loading, grain size distribution, screen selection, and properties along with operating conditions, and might be differ than specified and can be more than 400m³/h.

| Number installed | 2 no |

| Number of decks (each) | 1 no. |

| Deck angle adjustment | 0° bis +30° |

| Total screen area | 2.4 m² |

| Screen panels per shaker | 10 no. |

| Number installed | 2 no |

| Number of decks (each) | 1 no |

| Deck angle adjustment | 5° bis +3° |

| Total screen area | 3.2 m² |

| Screen panels per shaker | 4 no |

| Rated power (each with) | 6 x 3.6 kW |

| 4 x 2.2 kW | |

| Voltage | 400V / 50Hz / 3phase |

| Number installed | 4 no. |

| Diameter/ cone size | 305 mm (12”) |

| Cut point d50 | 25 μm[1] |

__________________________________________________________________________________________________________________________

[4] (at 1.1 bar + 4 x 78 m³/h)

regarded to – viscosity: 80 kg/m*s; density suspension: 1.47 kg/l; density dry content: 2.48 t/m³

| Number installed | 24 no |

| Diameter/ cone size | 102 mm (4”) |

| Cut point d50 | 5 μm[1] |

| Number installed | 2 no |

| Rated power | 75 kW |

| Voltage | 400V / 50Hz / 3phase |

| Number installed | 1 no. |

| Rated power | 90 kW |

| Voltage | 400V / 50Hz / 3phase |

_________________________________________________________________________________________________________________

[5] (at 3.3 bar + 24 x 15 m³/h)

regarded to – viscosity: 80 kg/m*s; density suspension: 1.47 kg/l; density dry content: 2.48 t/m³

Contact

Gewerbestraße 11a

26553 Dornum

Germany

Tel: +49-4933-4269975

E-Mail: info@diff-speed.de