Details

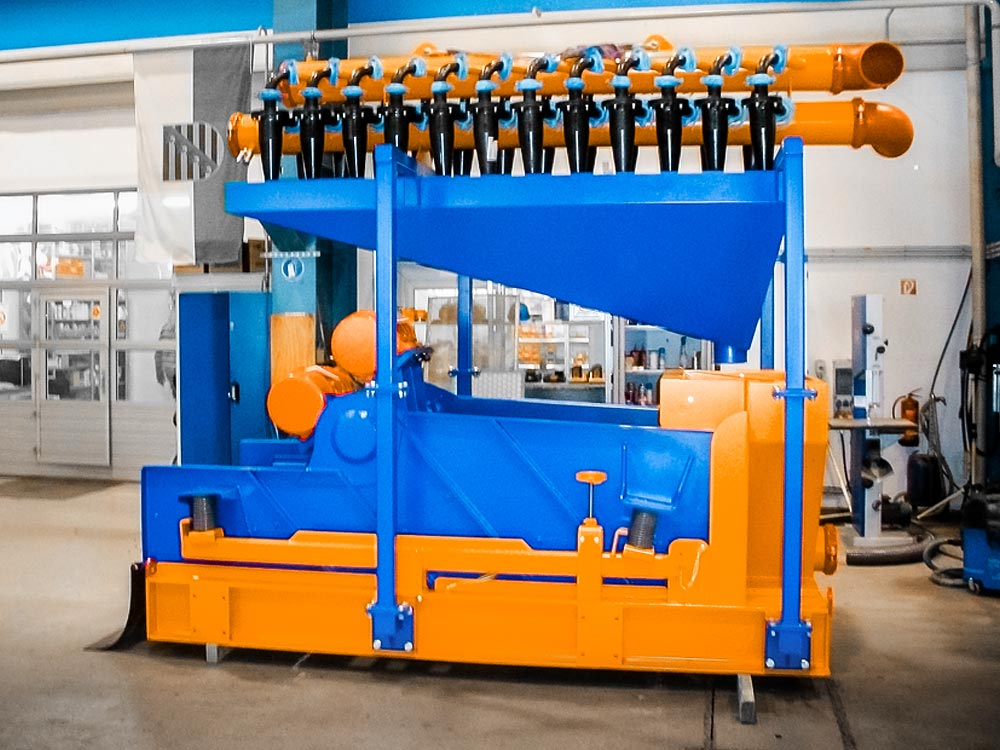

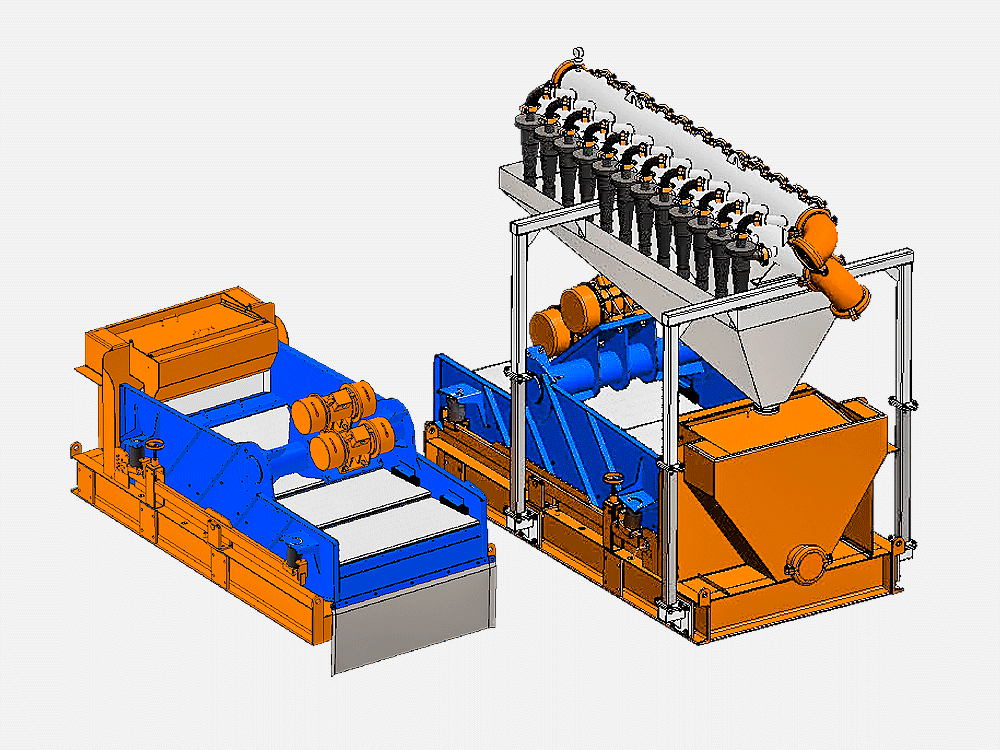

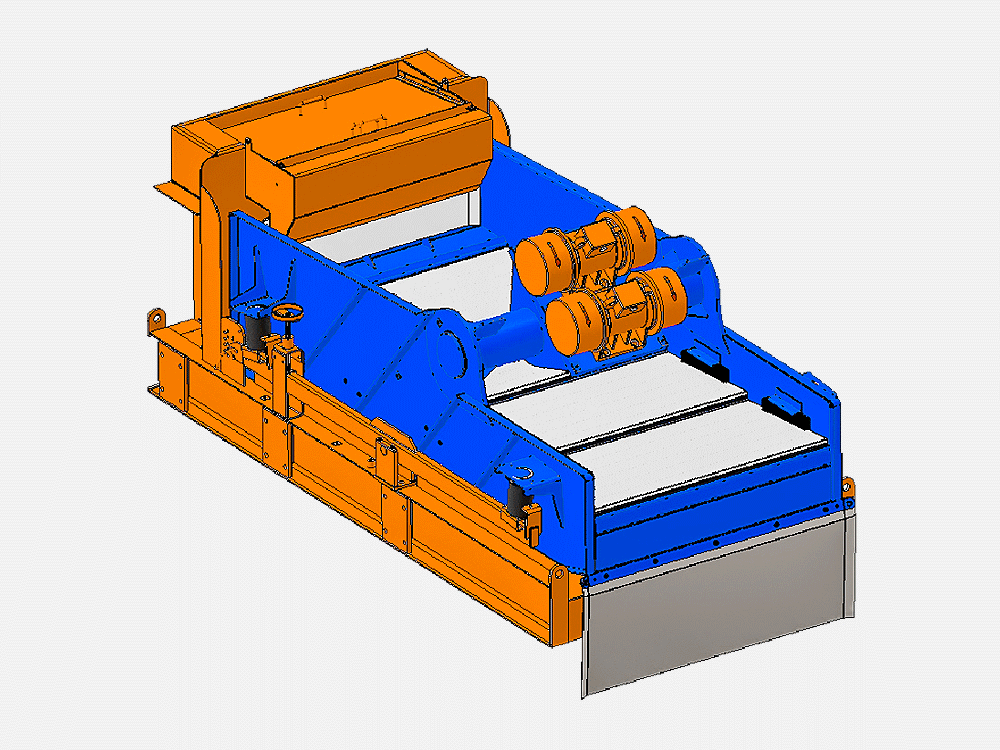

The 4-panel screening machine 4PSM is used to dewater heterogeneous solid-liquid mixtures. With an acceleration force of up to 6.3 G it sets the panel screens fine installed on it in motion, whereby the solid particles contained in the suspended suspension are dewatered. The grain size limit or the degree of fineness of the separation results from the mesh size of the sieves. Coarse screens made of polyurethane with mesh sizes from 11 x 3.5 mm to 11 x 0.3 mm and fine screens made from woven stainless steel with mesh sizes from 70 mesh (210 µm / 0.21 mm) to 325 mesh (45 µm / 0.045 mm) are available .

- Separation of fines in the critical range from 100 to 45 µm Equipped with four panel screens fine arranged on one level, which are available in stainless steel or polyurethane, depending on the application

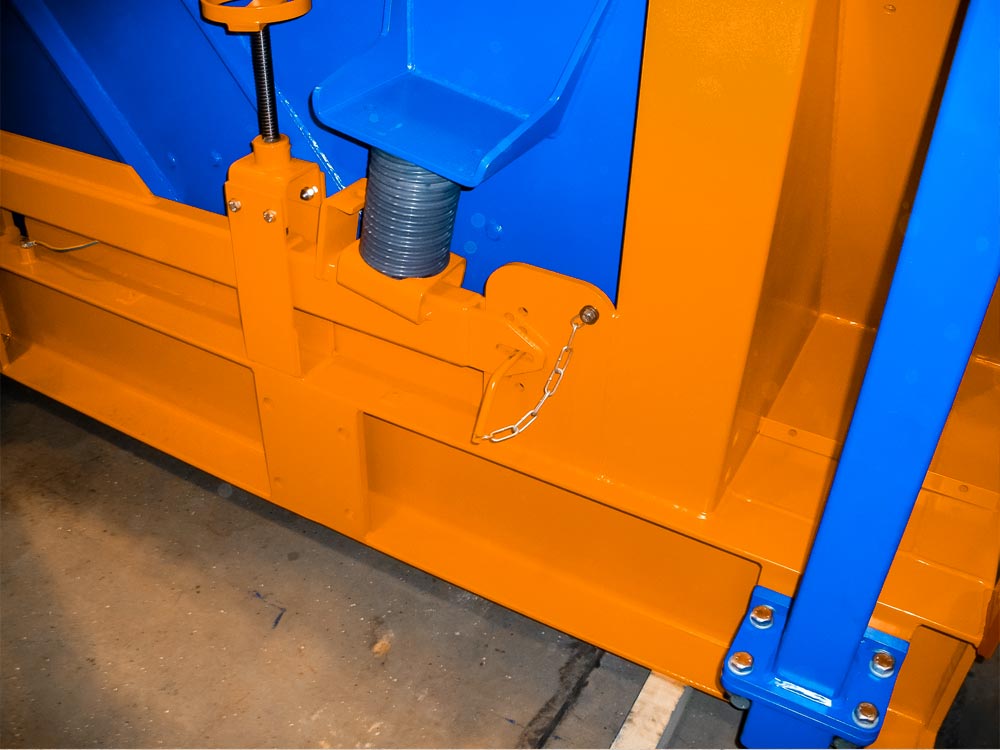

- Screen angle adjustment system for direct adjustment to the respective requirement situation thanks to the hammer wedge fastening system, the sieves can be exchanged quickly and easily

- Drilling fluids in the construction industry(e.g. tunnel construction, horizontal & vertical drilling)

- Industrial sludge (e.g. coke dust, tar oil, glass fiber-water mixtures)

- Agriculture (e.g. dewatering of cow dung or biowaste)

- Sludge dewatering in gravel and sand processing

| length | 3410 mm | |

|---|---|---|

| width | 1690 mm | |

| height | 1620 mm | |

| weight | approx.2380 kg |

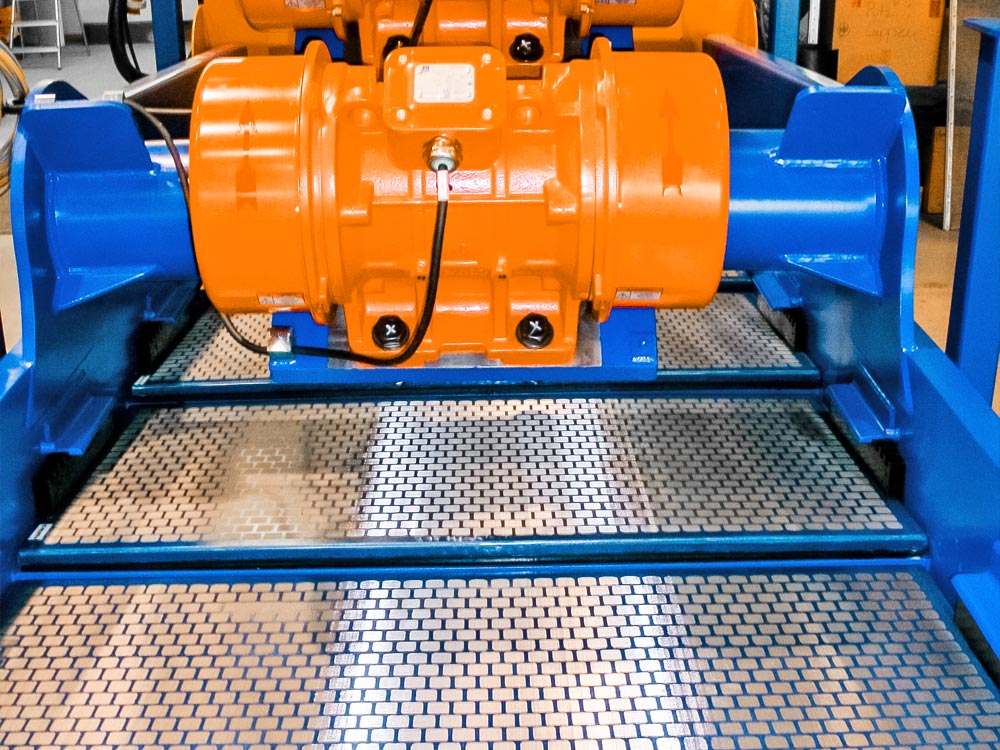

Vibration motors

| installed number | 2 pc |

| installed power (per motor) | 2x 3.6 kW |

| power supply | 400V / 50Hz / 3phase |

Panel screen fine

| installed number | 4 pc |

| movement type | linear |

| sieve area (total) | 3,2 m² |

| inclination angle | -5° bis +3° |

Contact

Gewerbestraße 11a

26553 Dornum

Germany

Tel: +49-4933-4269975

E-Mail: info@diff-speed.de